Vial Filling Machine

Function: Bottle Washing Filling Capping

Filling Material: Oral Liquid

Model: FCGF18-18-6

Capacity: 3000-6000BPH

Bottle Type: 10-100ml Small Glass bottle

Cap Type: Aluminum Plastic Cap with Inner Rubber Stopper

Machine material: SUS 304/316L

Overall size (L*W*H): 2450*1650*2500mm

Weight: 2800KG

Warranty: 3 Years

Vial Filling Machine

This FCGF Series Vial Filling Machine is mainly used for producing Oral Liquid in small glass bottle with Aluminum Plastic Cap (with inner rubber stopper).

The three functions of washing, filling and capping are in one unit. Whole process is automatic.

The height of bottle washing, filling and capping can be adjusted to adapt to different height containers, and it is convenient to replace bottle type.

The whole machine is designed scientifically and reasonably, the appearance is good looking, the maintenance and repair is rather convenient, the wastage rate is quite low.

It is the ideal equipment for mid-scale & small-scale Oral Liquid factory.

Overall View of Vial Filling Machine

Inner View of Vial Filling Machine

View of Washing Part

Washing Part of Vial Filling Machine

1).Enhanced food safety: Stainless steel 304/316L for all components in contact with liquid.

2).Each flushing head is equipped with a self-made stainless steel control water valve, which greatly saves water and reduces the residual water in the bottle.

View of Filling Part

Filling Part of Vial Filling Machine

1).304/316 Stainless steel high precision filling valves.

2).304/316 Stainless steel fine polish filling tank without death corner.

3).Filling valve adopts high filling speed and mass flow rate valve which control liquid level accurately without loss.

4).Liquid level in filling tank is controlled via float-ball.

5).Using micro negative pressure filling method to ensure the accuracy of liquid level.

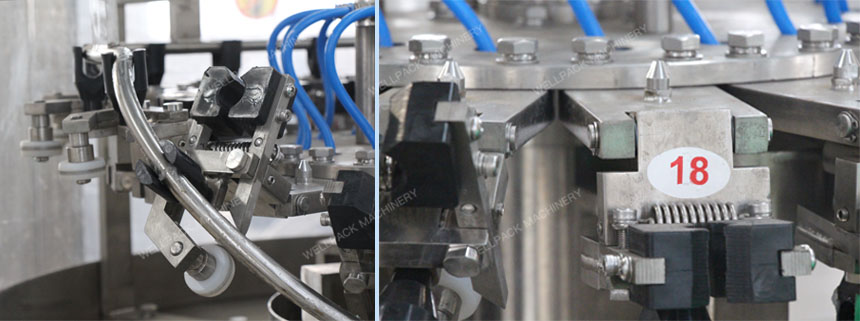

View of Capping Part

Capping Part of Vial Filling Machine

1).The capping machine includes capping head,cap unscrambler and cap tunnel.

2).The hopper is equipped with photoelectric switch to control the cap feeding automatically.

3).No bottle no capping. Automatic stop when lack of bottle.

4).The capping is continuous rolling type.

5).Capping effect is stable and reliable, defective rate ≤0.2%

(Output) Side View of Vial Filling Machine

Sealed Vial Samples

Vial Cap Samples (Aluminum Plastic Cap with Inner Rubber Stopper)

Reference Sheet Of Vial Filling Machine Series Equipment:

| Model | FCGF24-18-6 | FCGF32-24-8 | FCGF40-32-10 |

| Washing/Filling/Capping heads | 24-18-6 | 32-24-8 | 40-32-10 |

| Capacity: BPH (50ml bottle) | 3000-6000 | 5000-8000 | 8000-12000 |

| Bottle shape | Round & Square & Flat & Special shaped bottle | ||

| Bottle size | Diameter:10-50mm; Height:50-120mm | ||

| Cap type | Aluminum Plastic Cap with Inner Rubber Stopper | ||

| Filling precision | ≤±2mm | ||

| Power (KW) | 4.5 | 5.2 | 6.5 |

| Overall size (mm) (L*W*H) | 2650*1850*2500 | 3000*2200*2500 | 3800*2850*2500 |

| Weight (KG) | 3000 | 4000 | 5200 |

For more details & info. of the Vial Filling Machine, welcome to enquire now.