Liquor Bottling Equipment

Function: Bottle Washing Filling Capping

Filling Material: Spirits, Liquor, Alcohol, Wine

Model: FCGF32-24-8

Capacity: 5000-8000BPH

Packaging Type: 200-2000ml Glass bottle with Aluminium cap

Machine material: SUS 304/316L

Overall size (L*W*H): 3000*2200*2500mm

Weight: 4000KG

Certificate: CE ISO

Warranty: 3 Years

Liquor Bottling Equipment

This FCGF Series Liquor Bottling Equipment is mainly used for producing Spirits, Liquor, Alcohol, Wine etc. Non-gas contained drinks in glass bottle with Aluminum screw Cap.

The three functions of washing, filling and capping are in one unit. Whole process is automatic.

The height of bottle washing, filling and capping can be adjusted to adapt to different height containers, and it is convenient to replace bottle type.

The whole machine is designed scientifically and reasonably, the appearance is good looking, the maintenance and repair is rather convenient, the wastage rate is quite low.

It is the ideal equipment for mid-scale & small-scale liquor factory.

Overall View of Liquor Bottling Equipment

Front View of Liquor Bottling Equipment

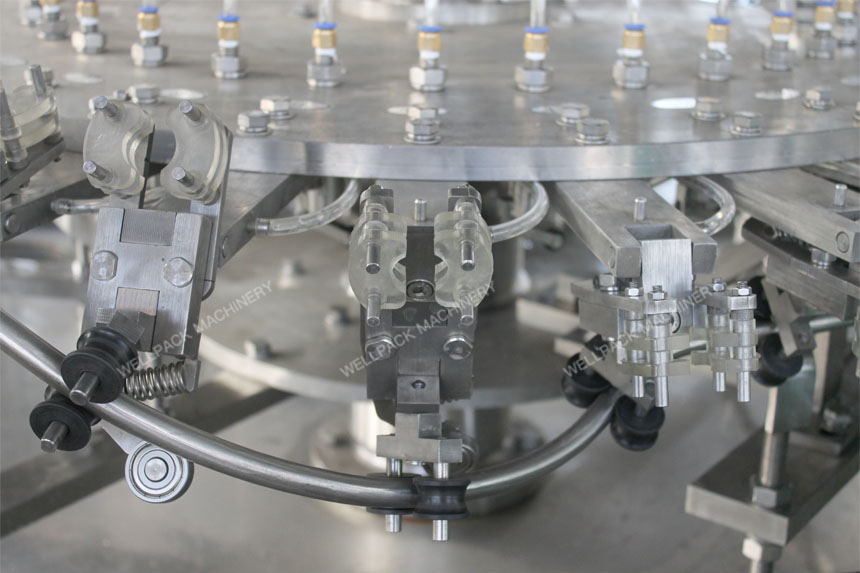

Inner View of Liquor Bottling Equipment

View of Washing Part

Bottle Washing:

1).Enhanced food safety: Stainless steel 304/316L for all components in contact with liquid.

2).Each flushing head is equipped with a self-made stainless steel control water valve, which greatly saves water and reduces the residual water in the bottle.

View of Filling Part

Bottle Filling:

1).304/316 Stainless steel high precision filling valves.

2).304/316 Stainless steel fine polish filling tank without death corner.

3).Filling valve adopts high filling speed and mass flow rate valve which control liquid level accurately without loss.

4).Liquid level in filling tank is controlled via float-ball.

5).Using micro negative pressure filling method to ensure the accuracy of liquid level.

6).The filling process bottle alignment is accurate: the filling machine has the Pre-cover function with centering cover, ensures the bottle mouth and filling valve mouth to seal accurately, eliminates the leakage phenomenon caused by the bottle body skew, and truly reduces the loss of spirits.

View of Capping Part

Bottle Capping:

1).The capping machine includes capping head,cap unscrambler and cap tunnel.

2).The hopper is equipped with photoelectric switch to control the cap feeding automatically.

3).No bottle no capping. Automatic stop when lack of bottle.

4).The capping is continuous rolling type. The lower part of the capping head has a centering cover, which makes the output of bottle more smoothly.

5).Capping effect is stable and reliable, defective rate ≤0.2%.

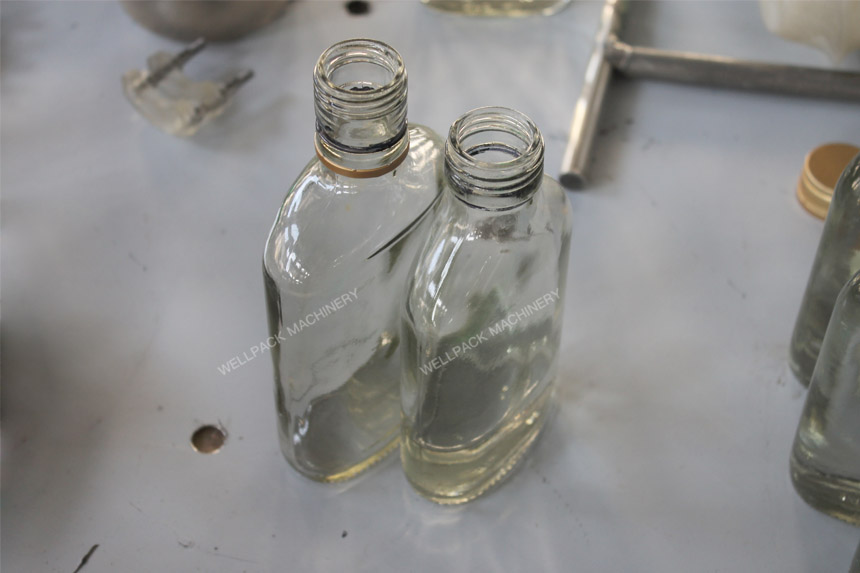

Glass Bottle Samples

Reference Sheet Of Liquor Bottling Equipment Series Equipment :

| Model | FCGF24-18-6 | FCGF32-24-8 | FCGF40-32-10 |

| Washing/Filling/Capping heads | 24-18-6 | 32-24-8 | 40-32-10 |

| Capacity: BPH (500ml bottle) | 3000-6000 | 5000-8000 | 8000-12000 |

| Bottle shape | Round & Square & Flat & Special shaped bottle | ||

| Bottle size | Diameter:50-100mm; Height:100-340mm | ||

| Cap type | Aluminum screw cap | ||

| Filling precision | ≤±2mm | ||

| Power (KW) | 4.5 | 5.2 | 6.5 |

| Overall size (mm) (L*W*H) | 2650*1850*2500 | 3000*2200*2500 | 3800*2850*2500 |

| Weight (KG) | 3000 | 4000 | 5200 |

For more details & info. of the Liquor Bottling Equipment,welcome to enquire now!